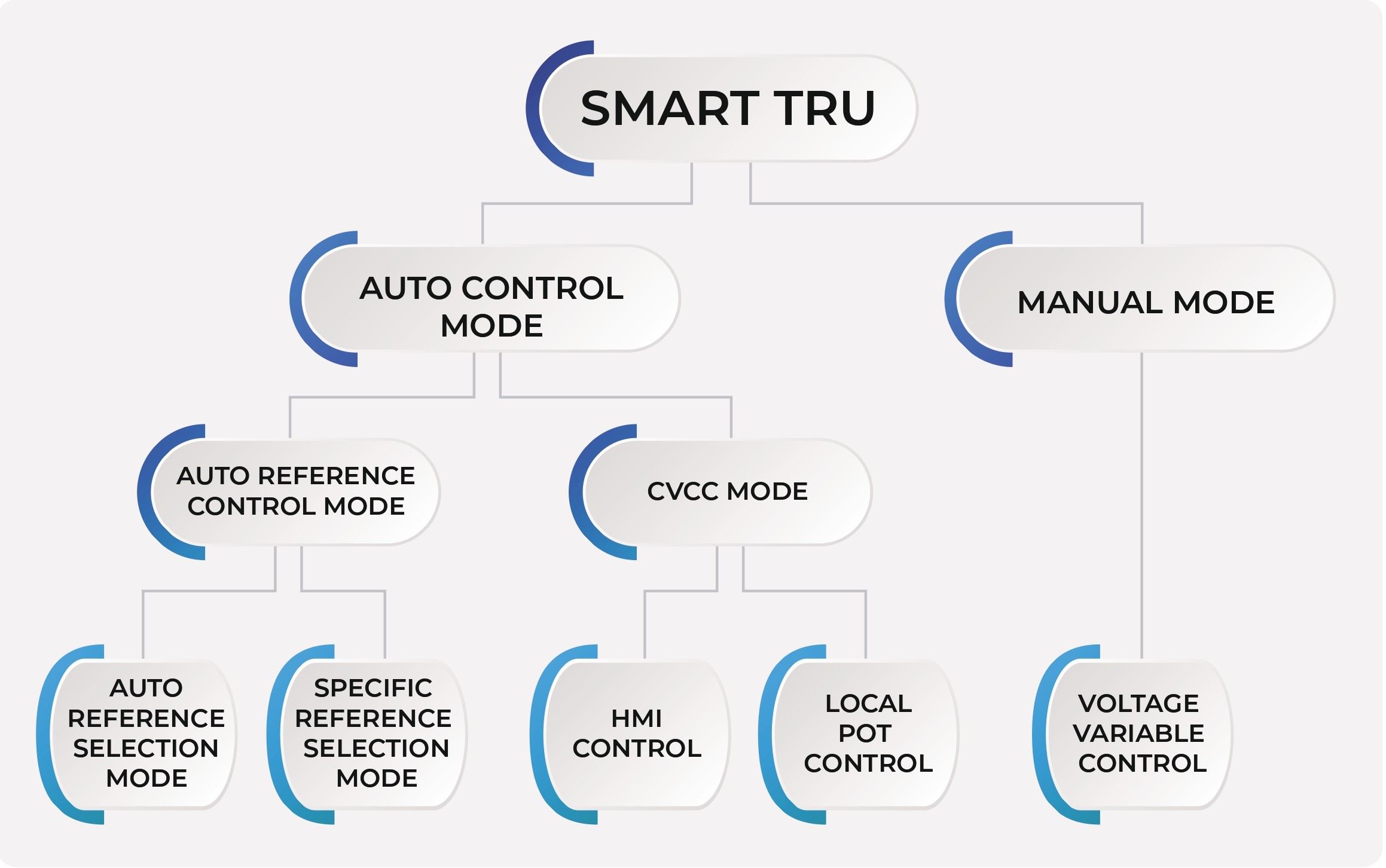

Cathodic Protection Transforme Rectifier unit (TRU) is a crucial component in safeguarding submerged

metallic structures from corrosion.

These structures can include buried pipelines, concrete structures (e.g., bridges buildings, sea ports) and

storage tanks at terminals/ refineries.

The primary goal of a TRU is to superimpose direct current (DC) onto the steel structure, opposing the galvanic corrosion currents, thus preserving the structure.